Mechanical engineers, construction co., transport producers & POP / exhibition displays, are all required to meet rising sustainability demands. Protective equipment has to offer durability, safety & security, whilst also providing an appearance that harmonizes with the application.

That is why increasing professionals are often choosing Green ✔ Tick Acrylic™ sheet, for

machine guards, glazing in the transportation & construction sector, for ice-rink barriers in

ice hockey stadiums, or in store security applications.

Green ✔ Tick Acrylic™ is one of the leading high quality & most versatile plastics. It can meet with general wear & tear workshop treatment & is simple to fabricate.

Green ✔ Tick Acrylic™ sheets are used in a variety of different applications, in the segments such as transport, signage, furniture, exhibitions & POP, sanitary ware, domestic applications, with also commercial architecture & construction, industrial applications, and a wide range of lighting applications. Quality, distribution of light, plus the energy efficiency created with LED illumination, are key requirements in modern lighting systems.

Green ✔ Tick Acrylic™ is one of the leading high quality & most versatile plastics. It can meet with general wear & tear workshop treatment & is simple to fabricate.

Green ✔ Tick Acrylic™ sheets are used in a variety of different applications, in the segments such as transport, signage, furniture, exhibitions & POP, sanitary ware, domestic applications, with also commercial architecture & construction, industrial applications, and a wide range of lighting applications. Quality, distribution of light, plus the energy efficiency created with LED illumination, are key requirements in modern lighting systems.

Green ✔ Tick Acrylic™ is the ideal substrate to meet these requirements. Its properties

with unsurpassed transparency & brilliance, a variety of surfaces, ease of thermo-forming,

meets with majority of the technical & design requirements of lighting engineers,

illuminated advertising/signage, light fixture manufacturers & specialist architects.

Green ✔ Tick Acrylic™ materials can be safely used as a product group in applications with the demand on the market for compliance, in all relevant health and safety aspects. Due to the manufacturing process, Green ✔ Tick Acrylic™ contains no plasticizers, heavy metal salts or halogens, & no levels of chlorine.

Green ✔ Tick Acrylic™ basic chemical structure, contains no nitrogen compounds or bisphenol A. Green ✔ Tick Acrylic™ normally emits no toxic or cancerogenic, mutagenic, teratogenic, even in the application of above the service & distortion temperature (around 100 °C - one hundred degrees Celsius). Due to the chemical chain structure, Green ✔ Tick Acrylic™ does not react with water, where it is widely used in aquatic applications.

Green ✔ Tick Acrylic™ solid sheets are extremely resistant to normal mechanical methods during installation & in application. Green ✔ Tick Acrylic™ offers 11(eleven) times the impact strength of conventional domestic glass.

Green ✔ Tick Acrylic™ materials can be safely used as a product group in applications with the demand on the market for compliance, in all relevant health and safety aspects. Due to the manufacturing process, Green ✔ Tick Acrylic™ contains no plasticizers, heavy metal salts or halogens, & no levels of chlorine.

Green ✔ Tick Acrylic™ basic chemical structure, contains no nitrogen compounds or bisphenol A. Green ✔ Tick Acrylic™ normally emits no toxic or cancerogenic, mutagenic, teratogenic, even in the application of above the service & distortion temperature (around 100 °C - one hundred degrees Celsius). Due to the chemical chain structure, Green ✔ Tick Acrylic™ does not react with water, where it is widely used in aquatic applications.

Green ✔ Tick Acrylic™ solid sheets are extremely resistant to normal mechanical methods during installation & in application. Green ✔ Tick Acrylic™ offers 11(eleven) times the impact strength of conventional domestic glass.

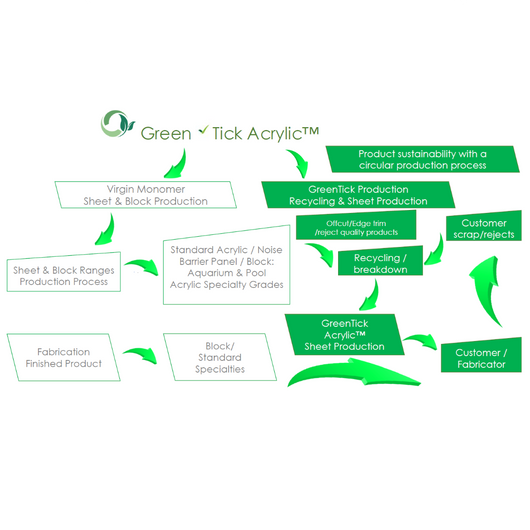

Green✔️Tick cast acrylic is a recent proprietary development in specialty acrylics,

utilizing innovative technology, by incorporating both recycled & virgin raw materials, into a

premium quality finished product.

Green✔️Tick is enabling the new generation of sustainable acrylic production, creating an environmental choice with the goal of assisting in the protection of our planet.

The Green✔️Tick proprietary process, simply enables the scrap/waste chemical alteration, further enabling the initial product regeneration, back into a newly produced sustainable finished material.

Green✔️Tick is enabling the new generation of sustainable acrylic production, creating an environmental choice with the goal of assisting in the protection of our planet.

The Green✔️Tick proprietary process, simply enables the scrap/waste chemical alteration, further enabling the initial product regeneration, back into a newly produced sustainable finished material.

We believe that the use of waste into society is an important process in addressing a

sustainable environmental future. Currently plastic products are categorized as throw away

items, where Green ✔️ Tick enables:

▶︎ Utilisation of scrap/waste, enabling a new life to a finished product.

▶︎ Reduced consumption of virgin raw materials.

▶︎ Reduced demand for landfill.

▶︎ Contribution to the protection of the environment.

▶︎ Free of VOC & HFC.

▶︎ The Green ✔️ Tick manufacturing, reduces our environmental impact. Substantially reduced infrastructure requirement & power consumption.

▶︎ Green ✔️ Tick Acrylic contains no hazardous substances such as heavy metals, hormone type products (bisphenol A) & no CFC or PCB like products.

Green ✔️ Tick acrylic has minimal effect on the environment, reducing our generations environmental footprint, making it the logical choice in fabrication. Green ✔️ Tick acrylic manufacturing process is unique, in reducing the consumption of water & energy, generating less CO2 emissions, further reducing our carbon footprint.

▶︎ Utilisation of scrap/waste, enabling a new life to a finished product.

▶︎ Reduced consumption of virgin raw materials.

▶︎ Reduced demand for landfill.

▶︎ Contribution to the protection of the environment.

▶︎ Free of VOC & HFC.

▶︎ The Green ✔️ Tick manufacturing, reduces our environmental impact. Substantially reduced infrastructure requirement & power consumption.

▶︎ Green ✔️ Tick Acrylic contains no hazardous substances such as heavy metals, hormone type products (bisphenol A) & no CFC or PCB like products.

Green ✔️ Tick acrylic has minimal effect on the environment, reducing our generations environmental footprint, making it the logical choice in fabrication. Green ✔️ Tick acrylic manufacturing process is unique, in reducing the consumption of water & energy, generating less CO2 emissions, further reducing our carbon footprint.

Green ✔️ Tick Acrylic™ sheet sustainability feature points:

• Manufactured from a high percentage % of recycled acrylic monomer/raw material (recycled Methyl Methacrylate - MMA), where the recycling process is continuous, through various finished products.

• GreenTick Acrylic™ sheet using existing materials & with a depolymerisation process, breaking the material down in one process to raw material.

New MMA production requires feed additives which requires their manufacturing process, then the further extensive processing with MMA production, where they are both long & detailed processes requiring extensive infrastructure & energy consumption.

• Manufactured from a high percentage % of recycled acrylic monomer/raw material (recycled Methyl Methacrylate - MMA), where the recycling process is continuous, through various finished products.

• GreenTick Acrylic™ sheet using existing materials & with a depolymerisation process, breaking the material down in one process to raw material.

New MMA production requires feed additives which requires their manufacturing process, then the further extensive processing with MMA production, where they are both long & detailed processes requiring extensive infrastructure & energy consumption.

Depolymerisation is a simple chemical process, breaking down the previous

polymerisation (curing) into pure raw MMA, with:

1. Less infrastructure & energy.

2. Significant reduction in previous prevalent issue with growing levels of land

fill.

• VOC & HFC free.

• Reduced water consumption, where it generates decreased levels of carbon dioxide

in the production process, as opposed to alternative virgin monomer cast acrylic

sheet.

• Manufactured with internally altered raw material, which creates a reduction in our

carbon footprint.

• Changes the process of processing of acrylic waste, which would be disposed of as

landfill or even further incinerated.

GreenTick™ Acrylic certiifies our statements to be true & correct.